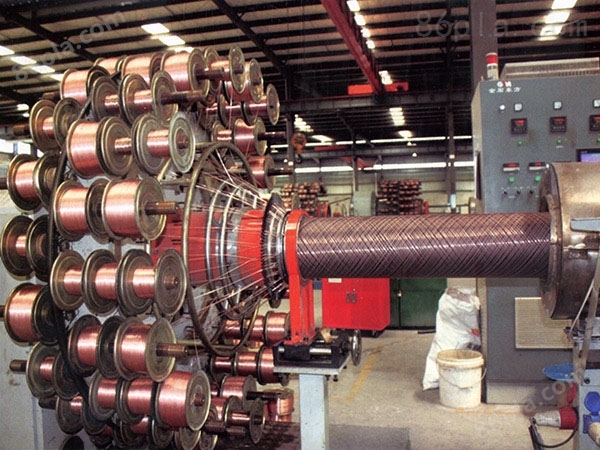

鋼絲網(wǎng)骨架聚乙烯復(fù)合管是以包覆處理后的高強(qiáng)度鍍銅鋼絲連續(xù)纏繞成型的芯層為增強(qiáng)骨架,以高密度塑料(聚乙烯)為基本材料,采用專業(yè)的熱熔膠(高性能改性聚乙烯粘接樹脂),在生產(chǎn)線上通過連續(xù)分次擠塑復(fù)合成型的管材。

廣泛應(yīng)用于長(zhǎng)距離埋地供水。供氣管道系統(tǒng),是目前國(guó)內(nèi)替換鋼管等傳統(tǒng)管道的優(yōu)選管材。

The steel wire mesh framework polyethylene composite pipe is a kind of reinforced core layer formed by continuouswinding of coated high strength copper-plated steel wire, and high density plastics (polyethylene) as the basicmaterial. It adopts professional hot melt adhesive (high-performance modified polyethylene adhesive resin) tocontinuously extrude and compound the pipe on the production line in stages.

It is widely used in long-distance buried water supply. Gas supply pipeline system is the preferred material forreplacing traditional pipes such as steel pipes in China.

產(chǎn)品性能

◆具有超過塑料管強(qiáng)度的較高強(qiáng)度、剛性、抗沖擊性。雙面防腐,具有與塑料管相同的耐腐蝕性能。

◆使用溫度提高, 導(dǎo)熱系數(shù)低,冬季使用外壁不需要保溫,夏季使用亦不結(jié)露。

◆內(nèi)壁光潔,不結(jié)垢,水頭損失比鋼管低30%。

◆管道連接采用電熱熔連接, 技術(shù)成熟,電熱熔接頭抗軸向拉力能力強(qiáng),管件品種多。

◆重量輕, 運(yùn)輸及施工方便,管材總體可靠性高。在正常條件下,使用壽命可達(dá)50年。

It has higher strength, rigidity and impact resistance than the strength of plastic pipe. Double-sided anti-corrosion, with the same corrosion resistance as plastic pipes.

The use temperature increases, the thermal conductivity is low, the external wall does not need thermal insulation in winter and does not condensate in summer.

The inner wall is smooth and scale-free, and the head loss is 30% lower than that of steel tube.

Pipeline connection adopts electro-thermal fusion connection, which has mature technology, strong resistance to axial tension of electro-thermal fusion joint, and many kinds of pipe fitings.

Light weight, convenient transportation and construction, high overall reliability of pipes. Under normal conditions, the service life can reach 50 years.

執(zhí)行標(biāo)準(zhǔn)

衛(wèi)生指標(biāo)符合GB/T17292《生活飲用水輸配水設(shè)備及防護(hù)安全性評(píng)價(jià)指標(biāo)》的規(guī)定。產(chǎn)品標(biāo)準(zhǔn)符合CF/T189- -2007。

The hygienic index conforms to GB/T 17292 "Safety Evaluation Index of Domestic Drinking Water Transportationand Distribution Equipment and Protection". The product standard conforms to CF/T189-2007.

技術(shù)要求

顏色一般為黑色,也可根據(jù)我供需雙方協(xié)商決定。管材內(nèi)、外表面應(yīng)該光滑平順,允許有自然收縮:的微小凹坑和凸起,不允許有氣泡裂口、分解變色及明顯劃傷,管材兩端切割平整。

The color is usually black. It can also be decided by negotiation between the supplier and the buyer. The inner andouter surfaces of the pipes should be smooth and smooth, allowing for natural shrinkage of small pits andprotrusions, not allowing bubble cracks, decomposition and discoloration and obvious scratches, smooth cutting atboth ends of the pipes.

應(yīng)用范圍

市政工程:城市給水、熱網(wǎng)回水、煤氣.天然氣輸送管道。

化學(xué)工程:酸、堿、鹽制造業(yè)、石化、化肥、制藥、化學(xué)、橡塑等行業(yè)輸送腐蝕性氣體、液體、固化粉末的工藝管及排放管。

油田氣田:含油污水、氣田污水、油氣混合物,二、三次采油集輸工藝用管。

熱電工程:工藝用水、回水輸送、除塵、廢渣等輸送管道。

冶金礦山:有色金屬冶煉中的腐蝕介質(zhì)輸送和礦漿、尾礦工藝用管。

高速公路:埋地排水管、電纜疏導(dǎo)管。

海洋工程:海水輸送、海底管線及光(電)纜導(dǎo)管等。

船舶制造:船舶污水關(guān)、排水管、壓艙水管、通風(fēng)管。

Municipal Engineering: Urban Water Supply, Heat Network Backwater, Gas and Natural Gas Pipeline.

Chemical engineering: process pipes and discharge pipes for conveying corrosive gases, liquids and solidifiedpowders in acid, alkali,salt manufacturing, petrochemical, fertilizer,pharmaceutical, chemical, rubber and plasticindustries.

Oilfield gas field: oil-bearing sewage, gas field sewage, oil-gas mixture, pipeline for secondary and tertiary oilrecovery gathering and transportation process.

Thermoelectric engineering: process water, backwater transportation, dust removal, waste residue and othertransportation pipelines.

Metallurgical mines: pipes for conveying corrosive media and pulp and tailings in non-ferrous metal smelting.Expressway: buried drainage pipe and cable dredging pipe.

Ocean engineering: sea water transportation, submarine pipelines and optical (electrical) cable conduits, etc.Shipbuilding: Sewage Gate, Drainage Pipe, Ballast Pipe, Ventilation Pipe.

給水、特種流體用管材公稱外徑。公稱壓力、公稱壁厚及極限偏差。

Nominal outer diameter of pipes for water supply and special fluids. Nominal pressure, nominal wall thickness andlimit deviation.

說明:

1、產(chǎn)品執(zhí)行標(biāo)準(zhǔn)為: CJ/T189- -2007《鋼絲網(wǎng)骨架塑料(聚乙烯)復(fù)合管材及管件》

2、同一規(guī)格不同壓力等級(jí)的復(fù)合管,其鋼絲直徑、網(wǎng)格參數(shù)不同;有特殊工況要求的供需雙方另行協(xié)商。

3、公稱壓力是管材在20C下輸送水介質(zhì)的使用壓力。若介質(zhì)溫度變化時(shí),應(yīng)進(jìn)行校正。

4、管材顏色一般為黑色,用戶提出特殊要求時(shí),由供需雙方另行約定。

產(chǎn)品的主要技術(shù)參數(shù)與規(guī)格

公稱壓力校正系數(shù)

在輸送20C以上或以下的介質(zhì)時(shí),管材的公稱壓力應(yīng)進(jìn)行修正,具體數(shù)據(jù)見下表:

The nominal pressure of pipes should be corrected when conveying medium above or below 20 degrees C. Thespecific data are shown in the table below.

鋼絲網(wǎng)骨架塑料(聚乙烯)復(fù)合管其他主要技術(shù)參數(shù)

OTHER MAINTECHNICAL PARAMETERS OF STEEL WIRE MESH FRAME PL ASTIC (POLYETHYLENE) COMPOSITE PIPE

物理機(jī)械性能(管材及電熔管件出廠檢驗(yàn)項(xiàng)目)

PHYSICAL AND MECHANICAL PROPERTIES (EX-FACTORY INSPECTION ITEMS OF PIPE AND FUSED PIPE FITTINGS)