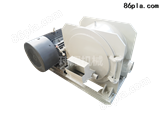

JS系列高精塑料磨粉機是將不同分子結構塑料或非塑料類磨成粉末狀。工作進程是:原料通過定量的加料器均勻的送入磨室中,再由吸風機將磨好的粉末吸出磨室,經過篩選機篩選,較大顆粒再次被送入磨室中再研磨。塑料制品廠實踐證明,在原料中加入粉體30%,將使其更好的塑化,且其制品的物性不變。因此,此機是塑料廠的利器設備。磨粉機 塑料超細磨粉機 450中型高精密磨粉機

JS Series high-precision plastic milling machine is a variety of different molecular structure of plastic or plastic ground into power .The work process are: raw materials both through quantitative feeder Smoothing into the grinding room, and then by the suction fan to suck out grinding mill good power room, through the screening machine, compared with grain particles was taken to the mill once again in the re-grinding. Plastic product Factory practice Certificate friends, and the raw material power 30%, will make it a better plasticizing properties and its products remain unchanged.

Therefore, this machine tool equipment plastic plant.

功能及特點Functions and features :

·全自動持續循環運作。磨粉機 塑料超細磨粉機 450中型高精密磨粉機

·結構緊湊,穩固,耐用。

·封閉式設計,利用自生風量與風壓,將粉末收集,無粉塵滲漏。

·定刀與磨盤間隙調動簡易,保養清料方便。 450中型高精密磨粉機

- Automatic continuous cycle operation

- Compact, solid and durable.

- Closed set right foot, and Kang using inferior of wind pressure. The power the end of the collection, without dust leakage.

- Fixed knife and the disc space mobility simple and maintenance easy clean materials.

技術參數:

型號/Type | JS-350 | JS-450 | JS-650 |

主機馬達Motor | 30HP | 50HP | 75HP |

風機馬達Blower | 5HP | 7.5HP | 10HP |

總功率Total Power | 27KW | 43KW | 63KW |

刀盤圓徑Cutter Diameter | 350 | 450 | 650 |

進料粒徑Feed Diameter | <6mm | <6mm < | <6mm |

出料細度Discharging pin size | 10~80 mesh > | 10~80 mesh > | 10~80 mesh > |

工作量Capacity (kg/h) | 50-100 | 80-180 | 100-350 |

機械尺寸L×W×H | 1800×1200×3300 | 2200×1760×3800 | 2500×2200×4300 |