注塑機 擠出機 造粒機 吹膜機 吹塑機 吹瓶機 成型機 吸塑機 滾塑機 管材生產(chǎn)線 板材生產(chǎn)線 型材生產(chǎn)線 片材生產(chǎn)線 發(fā)泡設(shè)備 塑料壓延機

四川川大干燥科技工程有限責(zé)任公司

四川川大干燥科技工程有限責(zé)任公司

| 參 考 價 | 面議 |

產(chǎn)品型號

品 牌

廠商性質(zhì)其他

所 在 地成都市

塑料機械網(wǎng)采購部電話:0571-88918531 QQ:2568841715

QQ:2568841715

聯(lián)系方式:查看聯(lián)系方式

更新時間:2023-07-27 09:37:13瀏覽次數(shù):308次

聯(lián)系我時,請告知來自 塑料機械網(wǎng)暫無信息 |

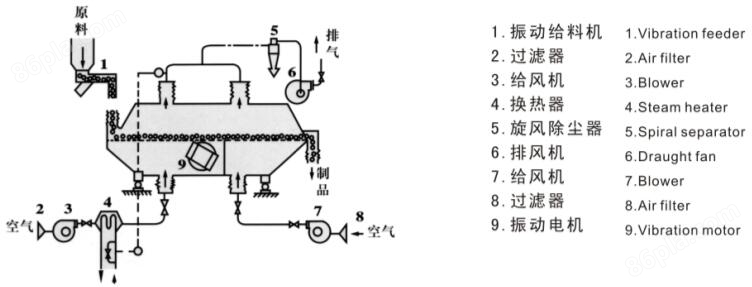

一、工作原理及應(yīng)用范圍介紹IntroductionofWorkingPrincipleandScopeofApplication物料從進料口進入床體內(nèi)

物料從進料口進入床體內(nèi),床體振動電機或其他方式提供的激振力作用下作一定頻率的振動,先經(jīng)過濾凈化然后經(jīng)加熱到一定溫度后的熱空氣經(jīng)入風(fēng)口進入干燥機下風(fēng)分配室然后再均勻穿過流化床板,物料在振動分散力和經(jīng)空氣分布板均風(fēng)的熱氣流雙重作用下,呈懸浮狀態(tài)與熱氣流接觸,物料顆粒與熱介質(zhì)之間進行著激烈的湍動,使傳熱和傳質(zhì)過程得以強化,干燥后的產(chǎn)品由排料口排出,蒸發(fā)出的水份和廢氣經(jīng)旋風(fēng)分離器回收粉塵后,排入大氣。下床體為床層提供了一個穩(wěn)定的具有一定壓力的風(fēng)室。調(diào)節(jié)引風(fēng)機,使上箱體中床層物料上部保持微負壓,維持良好干燥環(huán)境并防止粉塵外泄。

振動流化床干燥機用于顆料狀、粉末狀物料干燥的新型流態(tài)化高效干燥設(shè)備,適用于化工、制藥、食品、脫水蔬菜、糧食、礦產(chǎn)等行業(yè)。也可以用于物料冷卻、增濕作業(yè)。該機組能大批量、長期連續(xù)的進行生產(chǎn)。節(jié)能型振動流化床

Material enters the bed via the feed opening and vibrates at a certain frequency under the exciting force provided by the vibration motor of bed or in other way; the hot air which is filtered and purified firstly and subsequently heated to a certain temperature enters the drier downwind distribution chamber via the air intake vent and subsequently runs through the fluidized bed plate. Under the dual action of the vibration dispersion force and the hot air distributed uniformly by the air dispersion plate, the material in the suspending state contacts with the hot air. The drastic turbulence between the material particles and the heat media enhances the heat and mass transfer process. The products dried are discharged via the discharge opening; water and waste gas are discharged to the atmosphere after dust is collected by the cyclone separator. The lower bed provides a stable air chamber with stable pressure for the material layer. Induced draft fan is adjusted to maintain tiny negative pressure at the top of the material in the upper box so as to keep a good and dry environment and prevent dust from escaping. The vibro fluidized dynamic drier is a novel fluidized high-efficiency drying equipment used for drying pelletized and powder-like materials. It is suitable for such industries as chemical engineering, pharmaceuticals, food, dehydrated vegetables, grains and minerals, and also suitable for material cooling and humidification operation. This unit can be put into mass and long-period continuous production.

1.物料受熱均勻,熱交換充分,干燥強度高,比普通干燥機節(jié)能30%左右。

2.可調(diào)性好,適應(yīng)面寬,料層厚度和在機內(nèi)移動速度以及全振幅變更均可實現(xiàn)無級調(diào)節(jié)。

3.振動源是采用振動電機驅(qū)動,運轉(zhuǎn)平衡、維修方便、壽命長。

4.振動有助于分散濕含量大、易團聚、粘結(jié)的顆粒,改善流化狀態(tài),流態(tài)化穩(wěn)、均勻,無死隙和吹穿現(xiàn)象,可以獲得均勻的干燥、冷卻、增濕效果。

5.對顆粒物的破碎以及磨損較少,可用于易碎的干燥,物料顆粒不規(guī)則時亦不影響工作效果。

6.由于施加振動,可使最小流化氣速降低,因而可顯著降低空氣需求量,進而降低粉塵層夾帶,配套熱源,風(fēng)機,旋風(fēng)分離器等也可相應(yīng)縮小規(guī)格。

1.The material is heated evenly with sufficient heat exchange and high drying intensity. Its energy saving is 30% higher than the ordinary driers.

2.It has great adjustability and wide applicability. The thickness of material layer, the running speed in the drier and the change of double amplitude are step-less controllable.

3.Vibration is driven by the vibration motor featured by smooth operation, easy to repair and long service life.

4.Vibration is helpful to disperse the particles which have high moisture content and are easy to clot and cohere and improving the fluidized state, so that fluidization is stable and uniform, without dead space and blow-through, and uniform drying, cooling and humidification effects can be achieved.

5.It may make less particles crushed and abraded and can be used to dry the fragile particles. Its operating effect will not be affected even the particles of material are regular.

6.Vibration can reduce the minimum fluidizing air velocity, so the demand for air may decrease obviously and therefore dust entrainment will decrease. The sizes of supporting heat source, fan and cyclone separator etc may decrease accordingly.

您感興趣的產(chǎn)品PRODUCTS YOU ARE INTERESTED IN

塑料機械網(wǎng) 設(shè)計制作,未經(jīng)允許翻錄必究 .? ? ?

請輸入賬號

請輸入密碼

請輸驗證碼

請輸入你感興趣的產(chǎn)品

請簡單描述您的需求

請選擇省份

聯(lián)系方式

四川川大干燥科技工程有限責(zé)任公司